Tanning is crucial to the quality of leather. There are two tanning methods: mineral tanning (using chromium) and vegetable tanning, which is done using plant extracts.

The advantage of chrome tanning is its speed: less than 24 hours compared to a minimum of one month for vegetable tanning, and the versatility of tanning: chrome-tanned leathers can be very thin and become very supple; many colors are possible... they can therefore be used in almost all areas (shoes, leather goods, automotive, etc.). This tanning method has therefore become predominant in the leather industry. Chrome-based tanning is used for 99% of shoe leathers. To find out more about chrome tanning, here is an article on the subject published in the CTC (Centre Technique du Cuir) magazine.

The disadvantages are water pollution with chromium metal (even though European tanneries are all equipped with effective treatment plants) and the risk of allergies: The chromium used in tanning (chromium III) is completely harmless. It is chromium VI, which appears when tanning is poorly controlled, that is allergenic and aggravates fungal infections and is harmful to foot hygiene.

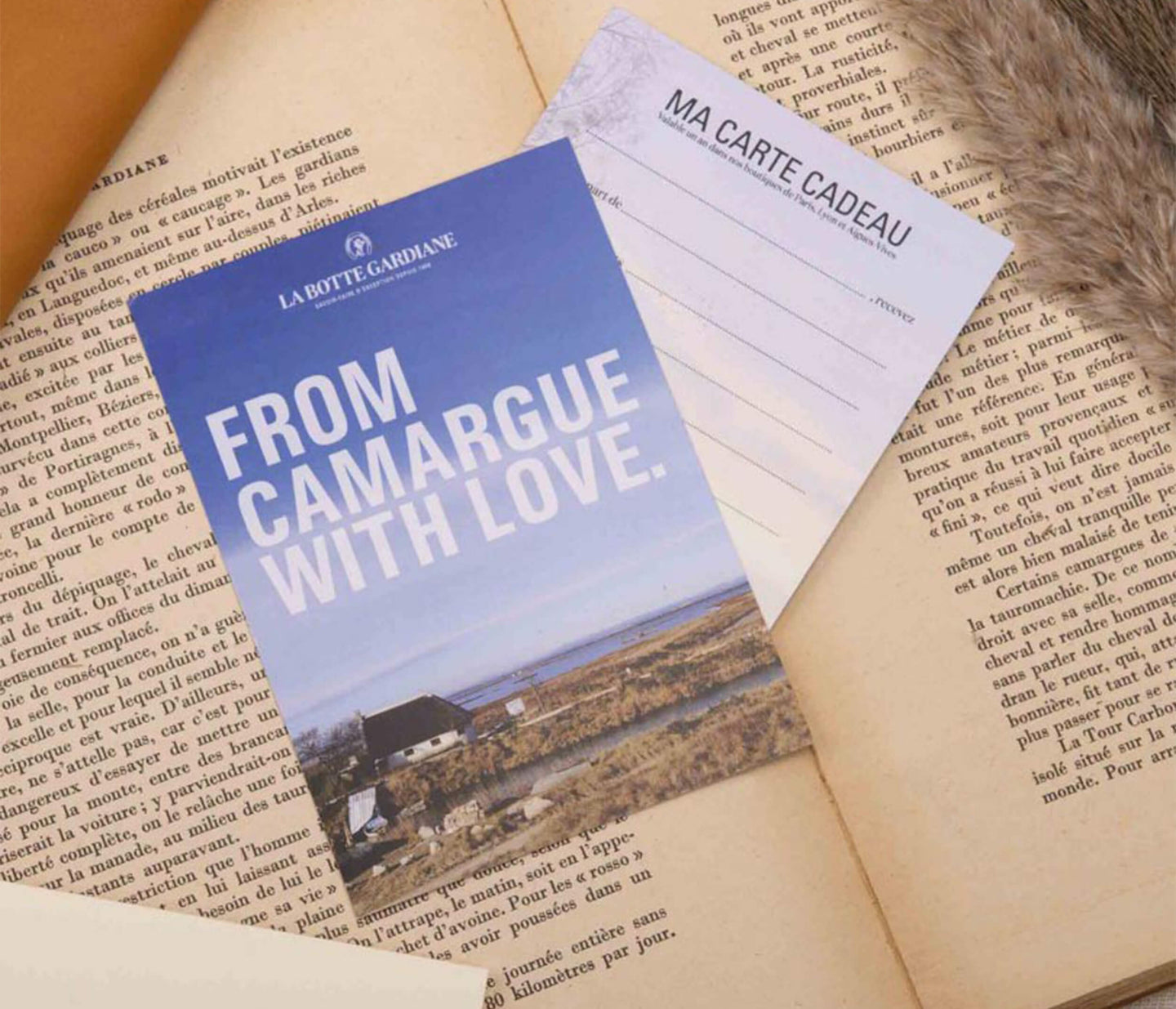

La Botte Gardiane offers a wide range of models in 100% vegetable-tanned leathers guaranteed chrome-free (supplied by a renowned Italian tanner, except for our Camargue calf vegetable-tanned leather, which is supplied by the Masure tannery), ensuring perfect foot hygiene and comfort. This type of leather is particularly suitable for people who are allergic to chromium salts, but also and above all for nature lovers.

Vegetable tanning is done using tannins (hence the origin of the word tanning) extracted from trees such as oak, chestnut, quebracho, mimosa, and acacia. This rather lengthy method (up to 18 months of soaking) led tanners to say, “to get good leather, you need tannin and time.” This process uses only plant extracts, is non-polluting, but uses a much larger amount of water. It is difficult to reconcile everything. By wearing our shoes made with vegetable-tanned leather, you will have eco-friendly and healthy products, entirely made in France, in our workshop located on the outskirts of the Camargue (between Nîmes and Montpellier).

Concerned about the environment, La Botte Gardiane works with suppliers for whom the concept of sustainable development is at the heart of their philosophy. A symbiosis between traditional facilities and modern tools enables these tanners and sole plate manufacturers to comply with European environmental standards. La Botte Gardiane is a member of ECO-TLC, the organization responsible for managing the collection and end-of-life of products. The aim is to preserve natural resources and reduce waste.